Efficient route planning is mission critical for trash valet services and waste management companies. But tackling routing manually results in massive headaches, bloated costs, missed service windows, and frustrated customers. Leveraging route optimization software and best practices is key to maximizing productivity, controlling expenses, and scaling sustainably.

But tackling routing manually results in massive headaches, bloated costs, missed service windows, and frustrated customers.

Leveraging route optimization software and best practices is key to maximizing productivity, controlling expenses, and scaling sustainably.

This comprehensive guide will walk through the end-to-end route planning process, best practices, and steps to start optimizing your trash valet routes right away with the help of DynoRoute's efficiency boosting techniques.

Why Route Optimization is Critical for Trash Valet Businesses

Route optimization helps trash valet and waste pickup companies:

- Reduce operating costs - optimized routing minimizes unproductive mileage, slashes labor and fuel expenses, and reduces equipment needs. Savings of 20-30% are common.

- Improve productivity - drivers can handle more stops per day, and trucks can reach full capacity. Stops per driver hour increases 22% on average.

- Meet service windows - precise ETAs and no backtracking means consistently reliable on-time arrival. Customer retention improves.

- Scale efficiently - increased capacity without inflating resources enables adding more customers without purchasing more trucks.

- Enhance safety - less rushed driving, detailed navigation, and streamlined operations create safer conditions.

Simply put, route optimization is table stakes for profitable, world-class valet trash operations today.

Step 1 - Collect and Centralize Route Data

The first step is compiling clean, accurate data on all the key inputs that determine your routes:

- Customer locations

- Requested service frequency

- Average pickup volume

- Vehicle capacity

- Driver shift hours

- Service time windows

- Special handling needs

This data typically resides across your CRM system, billing platform, manual records, and driver knowledge.

Centralizing the data in your optimization software ensures route planning utilizes the full picture. Garbage in = garbage out.

For example, Acme Waste gathers:

| Customer | Address | Service Day | Avg. Volume |

|---|---|---|---|

| Clancy’s Pub | 105 Main St | M, Th | 4 bins |

| Oak Hill HOA | 722 Oak Rd | Tu | 96 bins |

| Pristine Pools | 514 Commerce Ct | W, F | 2 bins |

Pro Tip: Assign unique IDs and geo-codes to each customer for easy software location mapping. Avoid common Trash Valet Route Planning Mistakes.

Step 2 - Configure Accurate Route Parameters

The second step is correctly configuring your key operational parameters and constraints:

- Driver maximum work hours

- Average travel speed

- Average service time per stop

- Vehicle capacity

- Service time windows

- Allowable turning restrictions

Properly tuned parameters enable the software to model realistic conditions and optimize accordingly.

For example, Acme Waste sets:

- 10 hour maximum driver day

- 25 mph average travel speed

- 10 mins per stop

- 96 bin truck capacity

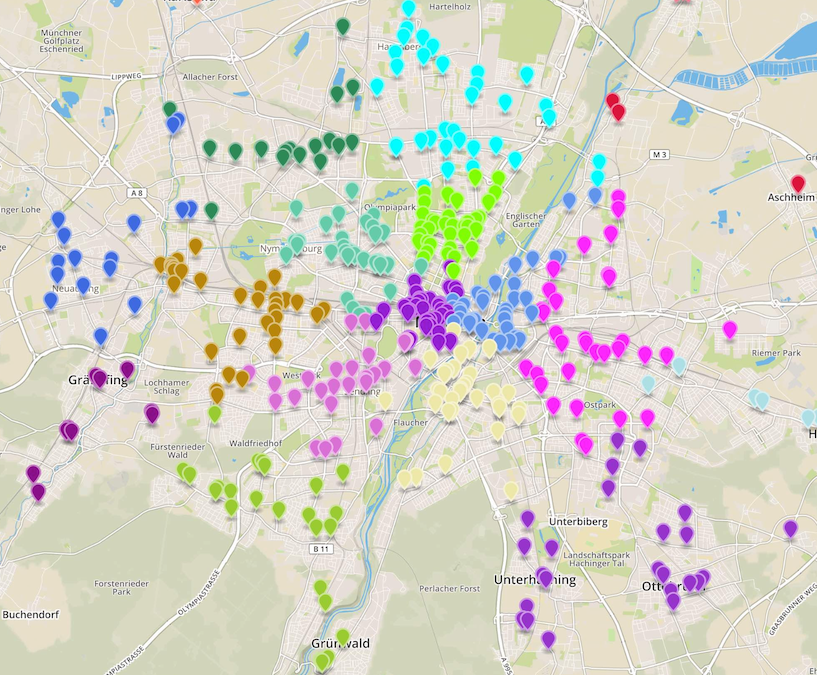

Step 3 - Cluster Nearby Stops

Next, identify clusters of stops in close proximity.

For example, look for multiple pickups on the same street, in the same neighborhood, or same office park.

Tight stop clusters significantly reduce deadhead travel time between pickups. This approach is especially impactful in dense urban areas.

Tip: Use heatmaps in your routing software to visually identify high-density clusters.

Step 4 - Balance Route Density

With stops clustered, work to balance total stops across routes at optimal density.

Density is measured by stops per mile or stops per hour. But don't overload to the point routes exceed truck capacity or driver limits.

| Route | Total Stops | Miles | Density |

|---|---|---|---|

| A | 45 | 12 | 3.75 stops/mi |

| B | 50 | 15 | 3.33 stops/mi |

| C | 55 | 11 | 5 stops/mi |

Here Route C has highest density at 5 stops per mile.

Shoot for maximum density until overflowing or exceeding constraints. This efficient balancing maximizes productivity.

Step 5 - Optimize Stop Sequencing

With balanced density, optimize the stop sequencing within each route:

- Prioritize high density clusters first

- Group stops with tight service windows

- Sequence to minimize deadhead travel between stops

Optimal stop order minimizes total mileage and windshield time during the route.

Step 6 - Set Route Direction

Define the general route direction to limit excess backtracking:

- Group stops travelling outbound then inbound

- Design loop routes when practical

- Leverage one-way street patterns

This eliminates wasteful cross-crissing enroute.

Step 7 - Generate Detailed Turn-by-Turn Directions

Provide drivers with exact optimized route guidance:

- Integrate sequenced routes into Google Maps

- Enable route visibility on driver devices

- Continuously update based on traffic

Clear optimized directions result in reliable on-time arrival at each stop.

Step 8 - Continuously Adjust Routes

Routes are living entities! Continuously adapt for:

- New customers

- Volume fluctuations

- Improved efficiencies

Ongoing refinements ensure maximum productivity is maintained over time. Check out these Top 10 Stats Showing the Impact of Route Optimization for Trash Valet Companies.

Start Planning Optimized Routes Today

Efficient route planning is crucial for trash valet operations. But tackling it manually results in bloated costs, frustrated customers, and limited growth.

Leveraging route optimization best practices and technology is the superior approach - slashing expenses, maximizing productivity, and enabling sustainability.

The benefits for your trash valet or waste pickup business are substantial:

27% reduced mileage

19% increased stops per driver

$22,000 annual savings per truck

+40% more customers serviced

Let DynoRoute's intelligent algorithms and easy-to-use software handle optimizing your pickup routes.

Focus your time on boosting customer satisfaction and profitability.

Start a You Dyno Route free trial today to experience the benefits yourself.